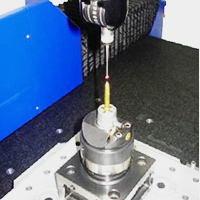

The SP25 is the right probe if you want to do form tests on workpieces. The SP25 can e.g. scan a circle at 20mm / s and record 1000 points. A very precise statement about the form deviation of the circle is then obtained. The measuring process is very quick. So if you have to record a high point density, the SP25 is clearly superior to a normal tactile measuring probe because it is much faster. You can also work with stylus lengths of up to 400mm. With the tactile probes from Renishaw, 100 stylus length is the limit. The use of the SP25 scanning system is the best solution, especially when the dimensions and shape of components have to be checked. The SP25M was developed for scanning and switching measurement. If required, all TP20 modules can be used. This makes you very flexible. The SP25 increases accuracy and productivity.

The SP25 scanning probe provides excellent accessibility to complex components. The use of long styli up to 400 mm and the possibility of working with a motorized rotary / swivel head such as the PH10M make you very flexible. The probe change magazine FCR25 also enables the automatic probe change. If necessary, additional extensions of the PEM series can be installed between the probe head and the scanning probe in order to be able to plunge even further into workpieces.

Renishaw scanning probe SP80

The SP80 scanning probe measures a casting

Scanning probe SP80 with long probe

Scanning probe SP80 measures a casting

The SP80 is a measuring probe for scanning that is mounted directly on the measuring quill. The use of the separate optical data acquisition (Isolated Optical Metrology) guarantees exceptional measuring performance, even with long styli. The SP80 can carry styli, including star stylus configurations, up to 500mm in length and up to 500g in weight without the need for counterbalancing. Renishaw's M5 styli are specifically designed for use with the SP80 and are extremely accurate. The removable stylus holder allows stylus configurations to be changed quickly and with repeatability without time-consuming recalibration. This increases the measurement throughput. The optimal stylus configuration can be used for every measuring application. The robust and simple design without motorized control offers high reliability and very good thermal stability.

The ability to use long and heavy stylus configurations with high accuracy makes the SP80 a first-choice scanning probe for a wide variety of measurement applications.

The stylus holder (SH80) can be exchanged automatically to increase the measurement throughput by attaching the memory modules (SCP80) to the modular exchange system (MRS).

The modular design allows the SP80 system to be expanded according to your requirements. The robust construction offers a long service life. In the event of service, Renishaw's rapid repair / replacement service ensures minimal downtime.

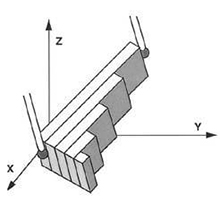

The SP80 determines the probe deflection directly and thereby achieves a very precise position determination. Various possible errors, such as thermal and dynamic effects, can also be recognized by the separate optical measurement value acquisition. In contrast to this, measuring probes with a conventional measuring arrangement of the axes must work with constantly changing inertial forces. This is due to the fact that when a stylus is deflected, it is necessary to move a larger mass in order to enable measurement values to be recorded in all 3 axes.

The separate optical recording of measured values can be explained as part of the system for recording measured values. The scanning heads are attached to the housing wall inside the probe and measure the deflection in every direction. All errors between the axes that are caused by the arc movement of each of the parallel working spring pairs are measured directly by the sensor system. The perpendicularity and straightness of the axes of the SP80 are not derived from the mechanism itself, but are determined by the moving element (moving cube).

Renishaw scanning probe SP600

Renishaw scanning probe SP600 with probe changer

Renishaw scanning probe SP600 with star stylus

The SP600 series offers maximum measurement accuracy when scanning and digitizing known shapes. The probes can be used on most CMMs. Renishaw's SP600 probe enables the rapid acquisition of large amounts of data for workpiece inspection or scanning. The buttons are suitable for a variety of industrial applications such as measuring gears, sheet metal shapes and shape measurements. The measuring probes can also be used to measure the finest details (e.g. pieces of jewelery, coins, buttons).

The SP600 series contains the SP600 measuring probe, a PC interface card and an interchangeable magazine for the styli. Together they provide a flexible system that meets most of the needs of today's CMMs.

SP600 probes are available in 3 versions:

Each of these measuring probes was developed to meet the most diverse requirements without reducing the performance features.

The SP600 consists of a basic body with an exchangeable stylus module. The main body contains the extremely robust, parallel working sensor mechanism. The stylus modules are fixed to the base body via a kinematic bearing. This enables a quick and repeatable module change and avoids time-consuming recalibration. Stylus modules can be changed manually or automatically with the SCR600 change magazine. Accuracy, speed and exceptional performance.

Renishaw probe TP20

probe changer MCR20 for TP20

Different modules of the Renishaw probe TP20

Renishaw TP20 probe

The Renishaw TP20 measuring probe is a 5-way switching probe. A 6-way probe module is also available for probing with a star probe. The button modules are exchanged with high precision and reproducibility via a magnetic coupling. It can be changed manually or CNC. You can continue working immediately after changing the button. Recalibration is not necessary because the change process has a reproducibility of about 0.5 µm and can therefore be carried out with great precision. The probe modules with different probing forces enable optimal adaptation to the respective measuring task. Extended EM push button modules are also available, as is a 6-way push button module for star buttons. The M2 connection thread allows the use of all Renishaw M2 styli. The TP20 measuring probe can also be retrofitted very easily on old measuring machines.

The MCR20 stylus change magazine from Renishaw can hold up to six TP20 stylus modules. With CNC measuring machines, the probe modules can be changed automatically. The MCR20 stylus change magazine was developed for the safe storage of the stylus modules and for quick, automatic module changes. At the same time, it protects the button modules from contamination.

The MSR1 storage system from Renishaw offers 6 storage spaces for already calibrated TP20 pushbutton modules. It simplifies the measuring process with manual measuring machines and provides additional protection for the TP20 modules. The MSR1 can either be attached to the measuring machine table or to a bracket for wall mounting.

| Tastermodul | Bild Tastermodul für TP20 | Anwendung für TP20 Tastermodule | Antastkräfte | Tastereinsatzlänge |

|---|---|---|---|---|

| Standard-Antastkraft | Geeignet für die Mehrzahl aller Anwendungen | XY: 0,08N Z: 0,75N Tastereinsatz: 10 mm |

10 - 50 mm | |

| Geringe Antastkraft | Anwendungen mit geringer Antastkraft z.B. Gummidichtungen | XY: 0,055N Z: 0,65N Tastereinsatz: 10 mm | 10 - 30 mm | |

| Mittlere Antastkraft | Anwendungen, die eine höhere Antastkraft erfordern | XY: 0,1N Z: 1,9N Tastereinsatz: 10 mm | 10 - 60 mm | |

| Hohe Antastkraft | Lange Tastereinsatzkombinationen und Anwendungen, bei denen Vibrationen ungewollte Tastsignale auslösen |

XY: 0,1N Z: 3,2N Tastereinsatz: 25 mm | 10 - 60 mm | |

| 6-Wege | Messungen in –Z Richtung - z.B. Inneneinstiche | XY: 0,14N Z: 1,6N Tastereinsatz: 10 mm | 10 - 50 mm | |

| 50 mm Verlängerung Gesamtlänge 75 mm |

Für die Mehrzahl aller Anwendungen, die eine 50 mm Verlängerung erfordern. Das Messtastermodul hat eine Gesamtlänge von 75 mm. | XY: 0,08N Z: 0,75N Tastereinsatz: 10 mm | 10 - 50 mm | |

| 75 mm Verlängerung Gesamtlänge 95 mm |

Für die Mehrzahl aller Anwendungen, die eine 75 mm Verlängerung erfordern. Das Messtastermodul hat eine Gesamtlänge von 95 mm. | XY: 0,08N Z: 0,75N Tastereinsatz: 10 mm | 10 - 50 mm |

A compact measuring probe with probe module change based on strain gauge technology and offering greater accuracy and a longer service life than conventional, mechanically switching probes. The TP200 measuring probe uses a sensor based on strain gauge technology, which guarantees excellent reproducibility and highly accurate 3D free-form measurements, even with long styli. The sensor technology generates excellent repeatability and eliminates the so-called "lobing" that occurs with kinematic measuring probes. The strain gauge technology guarantees measurements of several million probes with constant accuracy.

With the SCR200, up to six TP200 stylus modules can be changed quickly and automatically. The SCR200 is controlled by a separate interface (PI200) and has collision protection to prevent damage when driving over the change position. The SCR200 is available as an LF and SF kit, with both kits containing an SCR200 and three stylus modules of the appropriate force.

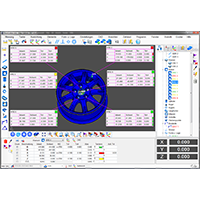

Fast measurement results thanks to simple operation.

Touch probes suitable for every application.

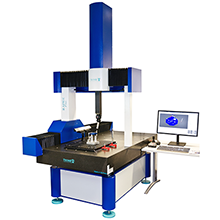

Manual measuring machine for quick and easy measurements.

CNC measuring machine for quick and easy measurements.

Electrode offset data and workpiece offset data for automatic transfer to EDM machines.

Acceptance test and confirmation test for coordinate measuring machines