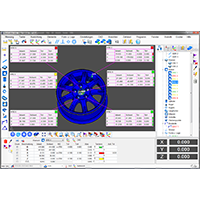

The measurement software ThomControl is very easy to use and extremely easy to use. Extensive graphic support allows even inexperienced operators to measure efficiently and quickly after just a few days. Measuring programs can be taught in using the teach-in process. The elements can be clicked directly on a CAD model and measured. The measuring program is written in the background.

Setpoints are automatically generated by simply clicking on the CAD. With the free-form surface module, surface points can be touched directly. The associated setpoint and the deviation from the CAD model are automatically determined and displayed graphically.

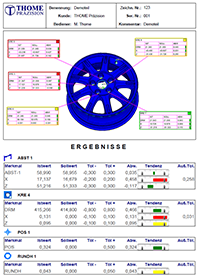

When printing the measurement protocols, the output can be sorted according to various criteria. The operator can also individually determine which element is to be output at which position in the measurement report. The measurement logs can be saved in PDF, WORD and EXCEL format. The clear report editor enables the quick and easy creation of graphical, tabular or combined measurement reports.

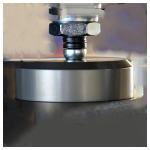

The granite guides of the THOME coordinate measuring machines are finely lapped. Due to its tension-free and thermal stability, granite is the ideal guide material for high-quality coordinate measuring machines.

Thanks to the high surface quality of the granite guides, our measuring machines consume very little air. Our air bearing technology also guarantees frictionless storage of the guides with maximum reproducibility. The measuring machines work almost wear-free.

The manual measuring machine SMART is equipped with a two-stage fine drive in each axis. The two-stage fine drive enables easily accessible areas to be measured quickly and precisely. Measurements can be made slowly and carefully in hard-to-reach areas. The fine step allows precise positioning in the µm range.

The individual clamping in all axes enables the operator to clamp an axis quickly. As a result, the machine moves exactly parallel to the axis. A contour can be followed or probed within a defined plane. You can also align the workpieces very precisely if necessary.

The double passive vibration damping absorbs vibrations down to 40 Hz. Vibrations down to 10 Hz can be absorbed by using an active air membrane damping.

| # | Paket 1 | Paket 2 |

|---|---|---|

| Probe head/ probe | TP8 Manual turn / swivel head cannot be indexed |

TP8 Manual turn / swivel head cannot be indexed |

| Measurement software ThomControl |

Basic geometery | Basic geometery with CAD |

| Measuring range 600x400x280 |

€ 16,990 P643-G-TP8 |

€ 17,990 P643-C-TP8 |

| Measuring range 800x400-280 |

€ 17,490 P843-G-TP8-UK |

€ 18,990 P843-C-TP8-UK |

| Measuring range 600x500x280 |

€ 19,490 P653-G-TP8-UK |

€ 20,990 P653-C-TP80-UK |

| Measuring range 800x500x280 |

€ 21,490 P853-G-TP8-UK |

€ 22,990 P853-C-TP8-UK |

| Measuring range 800x600x280 |

€ 23,490 P863-G-TP8-UK |

€ 24,990 P863-C-TP8-UK |

Rigid probe head PH6 and high-precision measuring probe TP200 for use with star probes and, if required, with the SCR200 probe changing system.

| # | Package 3 | Package 4 |

|---|---|---|

| Probe head/ Probe | PH6 / TP20 Rigid probe head with 2 quick-change modules |

PH6 / TP20 Rigid probe head with 2 quick-change modules |

| Measurement software ThomControl |

Basic geometery | Basic geometery with CAD |

| Measuring range 600x400x280 | € 18,490 P643-G-PH6TP20-UK |

€ 19,990 P643-C-PH6TP20-UK |

| Measuring range 800x400x280 |

€ 19,490 P843-G-PH6TP20-UK |

€ 20,990 P843-C-PH6TP20-UK |

| Measuring range 600x500x280 |

€ 21,490 P653-G-PH6TP20-UK |

€ 22,990 P653-C-PH6TP20-UK |

| Measuring range 800x500x280 |

€ 23,490 P853-G-PH6TP20-UK |

€ 24,990 P853-C-PH6TP20-UK |

| Measuring range 800x600x280 |

€ 25,490 P863-G-PH6TP20-UK |

€ 26,990 P863-C-PH6TP20-UK |

Rotary swivel head MH20i from Renishaw

Rotary swivel head MH20i from Renishaw

Rotary swivel head MH20i from Renishaw

The rotary and swivel axes can be adjusted reproducibly in 15 ° steps. Reproducibility 1.5 µm with a swivel radius of approx. 70 mm.

| # | Package 5 Best selling |

Package 6 |

|---|---|---|

| Probe head/ Probe | MH20i Indexable rotating / swiveling head with quick-change modules |

MH20i Indexable rotating / swiveling head with quick-change modules |

| Measurement software ThomControl |

Basic geometery | Basic geometery with CAD |

| Measuring range 600x400x280 |

€ 18,890 P643-G-MH20i-UK |

€ 20,390 P643-C-MH20i-UK |

| Measuring range 800x400x280 |

€ 19,890 P843-G-MH20i-UK |

€ 21,390 P843-C-MH20i-UK |

| Measuring range 600x500x280 |

€ 21,890 P653-G-MH20i-UK |

€ 23,390 P653-C-MH20i-UK |

| Measuring range 800x500x280 |

€ 23,890 P853-G-MH20i-UK |

€ 25,390 P853-C-MH20i-UK |

| Measuring range 800x600x280 |

€ 25,890 P863-G-MH20i-UK |

€ 27,390 P863-C-MH20i-UK |