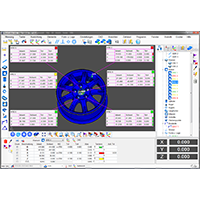

The measurement software ThomControl is very easy to use and extremely easy to use. Extensive graphic support allows even inexperienced operators to measure efficiently and quickly after just a few days. With the teach-in process, measuring programs can be taught in using a joystick. The elements can be clicked directly on a CAD model and automatically measured. The measuring program is written in the background. CNC probing strategies are available for all elements, which are displayed visually and can be configured as required.

The measurement program is created by simply clicking on the CAD elements. The target values are generated automatically and taken over from the CAD data record. This ensures the optimal vector approach to the measuring points. Any number of measuring points can be approached even in difficult zones.

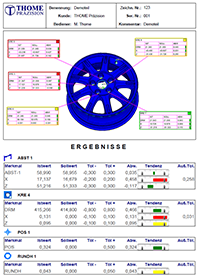

When printing the measurement protocols, the output can be sorted according to various criteria. The operator can also individually determine which element is to be output at which position in the measurement report. The measurement logs can be saved in PDF, WORD and EXCEL format. The clear report editor enables the quick and easy creation of graphical, tabular or combined measurement reports.

The guides of the column measuring machines with air bearings are mainly made of granite. The Y-arm is made of granite up to Y = 1,200mm travel. From a travel of Y = 1,200mm, the Y-arm is made of CFRP (carbon fiber composite). Carbon fiber materials are very light and have a very high strength. In addition, the material expansion coefficient can be made identical to granite. This means that the column measuring machines from THOME Präzision are very temperature-stable.

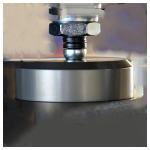

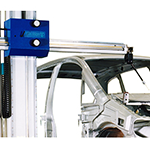

The drives and guides on all CNC column measuring machines are encapsulated with bellows. This guarantees protection against dirt, damage and thermal influences. Highly dynamic, backlash-free DC servo drives ensure precise, vibration-free positioning of our CNC column measuring machines. Handwheels and backlash-free and easy-to-use clamps are integrated in all axes of the manual column measuring machines. The button holder is compatible with conventional recording systems. Touch and scribing tools can be picked up from five sides.

Handwheels and backlash-free and easy-to-use clamps are integrated in all axes of the manual column measuring machines. The button holder is compatible with conventional recording systems. Touch and scribing tools can be picked up from five sides.

Thome Präzision builds both CNC column measuring machines and manual column measuring machines. The column measuring machines are available as single column measuring machines or as double column measuring machines. Special attention is paid to quality during production. Only selected guide materials such as granite, CFRP or special steel are used. This ensures the longevity and high accuracy of the column measuring machines.

Thanks to a well thought-out modular system, our measuring machines can be combined with almost any axis length. Depending on the measuring task, the axis lengths can be adapted to your needs.

Like all coordinate measuring machines from THOME Präzision, the column measuring machines can be equipped with a fourth axis. This is usually a rotary table. We use very precise rotary tables with an axial and radial runout accuracy of 0.5 µm. These rotary tables have air bearings and are individually selected according to workpiece size and workpiece weight.