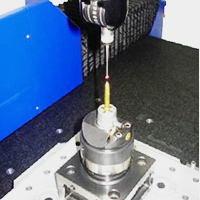

PH10M scanning probe head with 7.5° grid for tactile probes

Motorized pan and tilt head PH10M with scanning function

The PH10M is a motorized rotating/swivel head that was specially developed to increase the measuring throughput and allows the coordinate measuring machine to position the probe in space. This allows measurements from different angular positions without the need for frequent, time-consuming changes in stylus configurations. The PH10M is compatible with a wide range of contact and non-contact scanning probes as well as tactile touch probes, allowing the size, position and shape of critical features to be determined.

Renishaw's automatic probe changing systems, which can be used in conjunction with the PH10M, ensure fast and repeatable changing of probes and extensions without time-consuming recalibration, helping to maximize measurement throughput. The PH10M is a proven product, provides a cost-effective solution for automated measurement and is suitable for a wide range of applications.

The PH10M's automatic indexing reduces the need for frequent stylus changes, thereby increasing the measurement throughput. PH10M indexing is significantly faster than stylus changing.

The PH10M achieves a repeatability of 0.5 μm with a 62 mm swivel radius. This allows exact positioning even with long extensions.

Extensions up to 300 mm as well as all Renishaw probes with automatic changer or M8 thread can be used with the PH10M.

The PH10M works with a six-point kinematics which guarantees a high repeat accuracy of all 720 positions.

This fixture allows repeatable, automatic probe changing without time-consuming recalibration.

The PH10M can be used in conjunction with Renishaw's UCC controllers to provide a total solution.

The PH6M is a rigid probe. It has a multiwire interface and an autojoint mount. Therefore it is also suitable for use with scanning probes. It can be combined with the SP25M to form a compact and cost-effective scanning system.

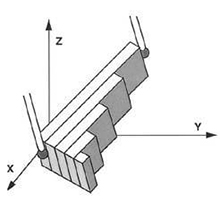

SP80 scanning probe from Renishaw

SP80 scanning probe from Renishaw

SP80 scanning probe from Renishaw

The SP80 is a probe for scanning, which is mounted directly on the measuring spindle. The use of Isolated Optical Metrology ensures exceptional measurement performance, even with long styli, and the SP80 can support styli up to 500mm long and 500g mass, including star configurations, without the need for weight compensation. Renishaw's M5 styli have been specifically designed to work with the SP80 and offer the highest accuracy. The removable stylus holder allows fast and repeatable stylus changes without the need for time-consuming recalibration. This increases the measurement throughput. The optimum stylus configuration can be used for each measurement application. The robust and simple design without motorized control offers high reliability and very good thermal stability.

The stylus holder (SH80) can be changed automatically to increase measurement throughput by attaching the memory modules (SCP80) to the modular changing system (MRS).

The modular design allows the SP80 system to be expanded according to your requirements. The robust design offers a long service life. When servicing is required, Renishaw's fast repair/replacement service ensures minimal downtime.

The SP80 determines the probe deflection directly and thus achieves a very accurate position determination. Various error possibilities, such as thermal and dynamic effects, can also be detected by the separate optical measurement value acquisition. In contrast to this, probes with conventional measuring arrangement of the axes must work with constantly changing inertial forces. This is due to the fact that the deflection of a stylus requires the movement of a larger mass in order to enable the measurement value acquisition in all 3 axes. The separate optical measurement value acquisition can be explained as a component of the system for measurement value acquisition. The scanning heads are mounted inside the stylus on the housing wall and measure the deflection in each direction. All errors between the axes caused by the arcing motion of each of the parallel spring pairs are measured directly by the sensor system. The perpendicularity and straightness of the SP80's axes are therefore not derived from the mechanism itself but are determined by the moving cube.

Fast measurement results thanks to simple operation.

Touch probes suitable for every application.

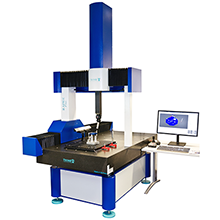

Manual measuring machine for quick and easy measurements.

CNC measuring machine for quick and easy measurements.

Electrode offset data and workpiece offset data for automatic transfer to EDM machines.

Acceptance test and confirmation test for coordinate measuring machines