Motorized pan and tilt head PH10T with 7.5° grid for tactile probes

Motorized pan and tilt head PH10T from Renishaw

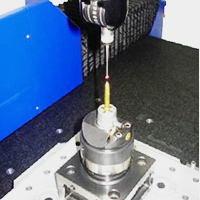

The PH10T is a motorized rotating/swivel head that was specially developed to increase the measuring throughput and allows the coordinate measuring machine to position the probe in space. This allows measurements from different angular positions without the need for frequent, time-consuming changes in stylus configurations. It is compatible with a wide range of tactile probes with M8 threads and extensions, allowing the size and position of critical features to be measured. The PH10T is a proven product and provides a cost-effective solution if the probe needs to be used in different positions in space.

The PH10T's ability to position automatically simplifies programming. There is no need to use expensive stylus configurations.

The PH10T achieves a repeatability of 0.5 μm at a swivel radius of 62 mm. This allows exact positioning even with long extensions.

Extensions up to 300 mm and all Renishaw probes with M8 thread can be used with the PH10T.

The PH10T works with a six-point kinematics which guarantees a high repeat accuracy of all 720 positions.

The PH10T can be used in conjunction with Renishaw's UCC controllers to provide a total solution.

Motorized turn and swivel head PH20

Motorized turn and swivel head PH20

Motorized turn and swivel head PH20

The PH20 probe head is another innovative probe product from Renishaw designed to optimise the performance of coordinate measuring machines (CMMs). For the first time, 5-axis technology for touch-trigger probes is available on CMMs of all sizes. The PH20 is available with your new CMM or as an upgrade to existing measuring machines.

The PH20 system's unique "head touch" method (head probing) allows measurement points to be acquired by moving the head rather than the CMM structure. Since only the fast rotary movement of the head is used, points can be acquired faster, with higher precision and improved repeatability. Furthermore, thanks to the 5-axis movement, time-consuming indexing of the head is no longer necessary. Together, these speed increases typically result in three times the throughput of conventional systems.

The PH20's unlimited positioning options guarantee optimum access to features with minimal stylus changes. Simultaneous 5-axis motion allows measurements of larger workpieces on a CMM, since the space around the workpiece required for head rotation is minimal. PH20 automatically aligns itself to the workpiece coordinate system, eliminating probe collisions and the need for accurate fixtures.

The unique calibration procedure developed for the PH20 probe head determines head orientation and probe position in a single operation and enables subsequent measurements at any angular position. (Improved measurement performance is available when needed by calibrating the probe tip in the orientation of the feature). This enormous time saving adds up especially for regular repeat calibrations, which are necessary to comply with quality processes or after a probe collision.

The PH20 probe head is combined with the proven TP20 probe modules, which offer different probing forces, directional positions and extensions to meet specific requirements. The removable modules provide collision protection and can be changed automatically using the MCR20 changing system.

Motorized swivel and rotation head REVO from Renishaw

The REVO™ system improves the measurement throughput up to 900%

The REVO™ system saves several hours of calibration time compared to conventional rotary/swivel heads.

The REVO™ system with Renishaw's Renscan5™ technology improves measurement throughput on coordinate measuring machines (CMMs) previously using 3-axis probing systems by up to 900% and saves several hours of calibration time compared to conventional swivel heads

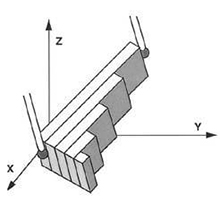

A decisive factor in the success of the REVO™ 5-axis measuring head is the ability to perform the scanning movement independently. This largely eliminates the dynamic errors caused by the acceleration/deceleration of the CMM's masses. The only way to ensure acceptable accuracy in 3-axis scanning was at the expense of measurement speed. REVO™, on the other hand, works with synchronized head and machine movements during scanning to quickly follow changes in part geometry without creating its own dynamic errors. This allows the CMM to move at a constant speed during the acquisition of measurement data without affecting accuracy.

With REVO™ the CMM operator also has the advantage of unlimited positioning possibilities of the measuring head, as well as the innovative tip-sensing probe technology, which further improves the measuring accuracy due to a very close contact to the measured surface. This combination of speed, flexibility and accuracy provides exceptional performance in a wide range of scanning applications, including circle, helix, sweep and flatness, as well as fast single touch probes when needed.

Renishaw believes the REVO™ system is rightly described as revolutionary, and highlights two automotive and aerospace applications where significant improvements in cycle times have been experienced by users. The first application is the measurement of blisks on aircraft engines, which required nine sector scans of the surface profile, eight longitudinal scans of the blade, two scans of the root circle profile and one scan of the ring profile. Originally, it was performed with a 3-axis scanning system, with one blade taking 46 minutes. With the REVO™ system, however, the process took only 4 minutes and 30 seconds, a considerable increase in throughput .

An almost equally drastic improvement has been achieved in the cylinder heads of motor vehicles, with the measuring sequence comprising twelve valve seats e and three circular scans on each of the twelve valve guide holes. Using the REVO™ system, the valve seats were measured at a speed of 400mm/sec and the valve guide at 50mm/sec. The total duration of the measurement process was only 3 minutes and 42 seconds. Compared to the original duration of 29 minutes and 13 seconds on a 3-axis system, the manufacturer achieved a 690% increase in throughput.

As Renishaw expects, the performance of its CMMs will be significantly enhanced through the use of REVO™ and Renscan5™ technologies, and will continue to revolutionise measurement throughput by reducing measurement times on high-precision components.

Fast measurement results thanks to simple operation.

Touch probes suitable for every application.

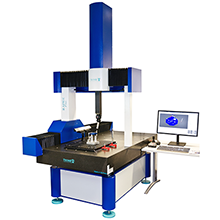

Manual measuring machine for quick and easy measurements.

CNC measuring machine for quick and easy measurements.

Electrode offset data and workpiece offset data for automatic transfer to EDM machines.

Acceptance test and confirmation test for coordinate measuring machines