The ThomControl measuring software is extremely easy to use and extremely convenient. Extensive graphic support allows even inexperienced operators to measure efficiently and quickly after just a few days. With the teach-in process, measuring programs can be taught in using a joystick. The ThomControl measurement software is based on the I ++ DME communication interface and can be used with all hardware components that support this interface. This means that old measuring machines from any manufacturer can be modernized (RETROFIT) very cost-effectively. ThomControl fulfills your measuring tasks quickly, easily and reliably and can be expanded to a higher level at any time.

The measurement software generates clear test reports that can be saved in PDF, Excel and Word formats. This software offers you an excellent price / performance ratio for both manual coordinate measuring machines and fully automated CNC-controlled coordinate measuring centers. The measurement software ThomControl is an in-house development from THOME Präzision GmbH and is programmed in Germany by experienced engineers and software developers. We can therefore offer you tailor-made measurement software that meets your very special needs.

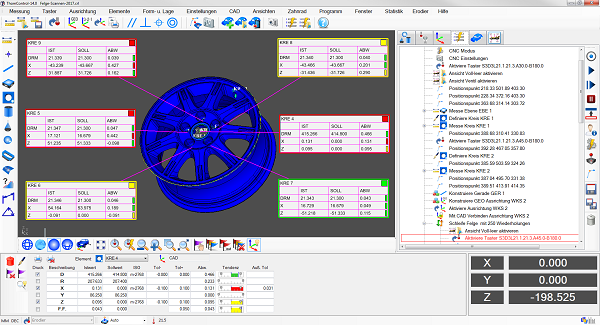

Simple operation thanks to a clear arrangement and easy-to-understand dialogues

A graphical real-time preview is obtained when creating the alignment

Tabular measurement report

Easy creation of alignments via the 3-2-1 alignment or the geometric alignment, each with a graphic preview. The alignments can be rotated and moved as required. The target values of the elements can be entered in clear windows and then measured fully automatically using a CNC strategy. A tolerance database with ISO tolerances according to DIN ISO 286 is integrated.

The last measurement result is displayed directly in the result window with a graphic trend bar. The operator can see all deviations at a glance. Comprehensive form and position evaluations such as parallelism, perpendicularity, coaxiality, position, evenness, straightness etc. are available. Measuring programs can be easily created and changed by double-clicking on a program line. Both CNC and manual measuring programs can be generated. All measurement results are saved and can be called up again at any time.

In addition to the internal file format of THOMControl, the measurement reports can also be saved in Word, Excel and PDF format. The measurement protocols can be easily adapted to your layout requirements. Several standard report templates are supplied. Various constructions of geometric elements enable extensive calculations of theoretical dimensions.

All elements are graphically displayed in 3D and can be graphically printed in the measurement report for better interpretation of the measurement results. ThomControl supports extensive construction methods such as BESTFIT, section of elements, middle element, parallel offset, etc.

All measuring probes can be calibrated on the CNC machines via an automatic probe calibration. This applies to rigid probe systems with star probes as well as to the swiveling probe heads. Measuring programs can be executed CNC or manually. Modern operator information can be generated. This enables important information to be passed on to the operator.

Individual measurements and measuring programs can be saved as required. The measurement results can also be saved in PDF, Word and Excel format. You can create any views and integrate them into the measurement program at any time. The views are managed in a clear view database.

Clear pull-down menus with images and graphic buttons for quickly calling up the most frequent commands ensure quick and easy operation. The ThomControl measurement software can be upgraded at any time so that you can also work with CAD support (description of this Modules can be found below).

Measurement strategies are displayed for all elements

With the RPS alignment, alignment against CAD can be carried out very quickly and precisely

The measuring software ThomControl with CAD import contains the full functionality of the ThomControl basic geometry described above. You also have the option of working with CAD files in IGES and STEP format and generating your measurements from the CAD data.

You can select any geometric elements via the CAD file with a mouse click and measure them automatically. The software suggests a measurement strategy and graphically displays the travel paths. The measurement strategy suggested by ThomControl can be changed as required.

The measurement program is created by simply clicking on the CAD elements. Setpoints are generated automatically and read from the CAD file. The optimal vector approach to the measuring points is thus guaranteed. Any number of measuring points can be approached even in difficult zones.

The integrated offline programming and simulation of the program sequences enables better utilization of your measuring machine, since the measuring programs can be generated without a real workpiece. Graphic result windows can be displayed for easy presentation of the results. The CAD models can be displayed as wireframe, transparent or solid.

Each measured area point is transferred to the element database and can be edited with a double click.

A form deviation of an element can be graphically displayed with one click.

The free-form surface module of the measuring software ThomControl is ideally suited for measuring against CAD data. CAD files in STEP and IGES format can be imported. ThomControl makes the comparison with the CAD model quickly and easily and provides the vectorial deviations point by point.

The alignment via 6 surface points, the RPS alignment and the best-fit alignment can be used for quick and precise alignment against a data set.

The measurement of cuts is easy e.g. by clicking the start and end point. The point density can be set individually. Surface forms can be measured using automatically generated point grids. Line and surface shape tolerances are calculated and displayed graphically.

A graphic form evaluation can be carried out using a one-click button, e.g. the line shape of a. The shape evaluation can then be recorded in a clear graphic printout.

The error enlargement factor can be used to clearly illustrate the form deviation and to adjust the view as required. The two red lines mark the limits of the permissible range. With the print button, the set view is transferred to the measurement report and can be printed out or saved as e.g. PDF file can be saved.

The temperature compensation can be done automatically or manually. With automatic temperature compensation, additional temperature sensors are attached to the measuring machine and read out by ThomControl. All the operator has to do is select the appropriate workpiece material and thus determine the coefficient of thermal expansion. With manual temperature compensation, the temperatures are determined by a thermometer and entered manually in a query mask.

With the internal statistics module, each measurement can be saved in a statistics database. The saved measurements can be called up and evaluated at any time. The statistical parameters mean value, standard deviation, range, CP value (capability) and CPK value (process capability) are available for the evaluation. In addition, a graphical course of the statistical measurement results is displayed. The measurement results can be printed out in a statistical measurement protocol and saved as an Excel, Word or PDF file.

The scanning option is necessary if you want to work with a continuous scanning button (e.g. SP25, SP80 from Renishaw). A large number of touch points can be measured within a short time. The scanning button remains in contact with the workpiece surface and continuously collects measuring points. The operator can define the point density as required. A typical scanning speed is between 5 and 25 mm / s. Scanning is primarily used to determine deviations in shape quickly and reliably.

First of all, the zero positions of the zero point clamping systems for the electrodes or workpieces are measured. With the usual clamping systems from EROWA, 3M or Hirschmann, correspondingly accurate reference bodies are supplied with which the reference systems can be measured. Afterwards, electrodes and workpieces can be measured in relation to your reference systems. The offset in X, Y and Z as well as the rotation around the C axis is determined. This data is either displayed graphically and printed out, or automatically passed on to the eroding machines (Ingersoll, ZimmerKreim, Sodick, Makino, etc.).

The eroding module is very easy to use. You can switch between eroding mode and normal measuring mode with one click. Simple macros are available for the most important electrode shapes and workpiece shapes. If the operator starts the macros, he is graphically guided step by step through the measurement. You can also create your own macros at any time. The offset data is clearly displayed on the screen and can be printed out or saved. You can also purchase a direct online connection to the EDM machine. Then the offset data can also be transferred directly to the eroding machine.

The measurement results can be exported in Q-DAS format. Q-The key fields can be filled and automatically written to a DFQ file when exporting. This DFQ file can be read in and evaluated by any software program that supports a Q-DAS interface. The Q-Das export command can be inserted into the measurement program so that the export takes place automatically.

With the Excel export to your own templates module, you have the option of creating your own Excel templates and filling them out with the measured values from ThomControl. The Excel files can also be filled in with the control of a measurement program. The specified Excel file is automatically filled with the measured values from ThomControl and then automatically saved under a new name.

With the help of the shrinkage module, a percentage of shrinkage in the 3 spatial directions or a shrinkage coefficient can be taken into account. Surface shapes can be measured using automatically generated point grids. Line and surface shape tolerances are calculated and displayed graphically. This allows measurements to be made on a casting mold, taking shrinkage into account, so that direct conclusions can be drawn about the dimensional accuracy of the final cast product.

The coordinate counter module enables the coordinate display to be enlarged over the entire screen. You can set each individual coordinate axis to zero at any point in the counter window or specify a desired start value for the axes. This module is particularly suitable for larger coordinate measuring machines in which the operator has to travel certain distances using the coordinate display or wants to approach certain values in a coordinate system.