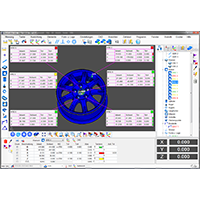

The ThomControl measurement software is very easy to use and extremely convenient. Extensive graphic support allows even inexperienced operators to measure efficiently and quickly after just a few days. With the teach-in process, measuring programs can be taught in using a joystick. The elements can be clicked directly on a CAD model and automatically measured. The measurement program is written in the background. CNC probing strategies are available for all elements, which are visually displayed and can be configured as required.

The measurement program is created by simply clicking on the CAD elements. The target values are generated automatically and taken over from the CAD data record. This ensures the optimal vector approach to the measuring points. Any number of measuring points can be approached even in difficult zones.

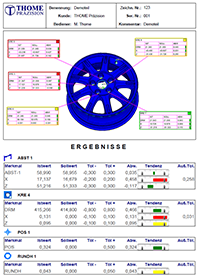

When printing the measurement protocols, the output can be sorted according to various criteria. The operator can also individually determine which element is to be output at which position in the measurement report. The measurement reports can be saved in PDF, WORD and EXCEL format. The clear report editor enables the quick and easy creation of graphical, tabular or combined measurement reports.

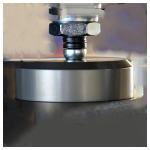

The granite guides of the THOME coordinate measuring machines are finely lapped. Due to its tension-free and thermal stability, granite is the ideal guide material for high quality measuring machines. Thanks to the high surface quality of the granite guides, our measuring machines consume very little air. Our air bearing technology also guarantees a frictionless bearing of the guides with the highest level of reproducibility. The measuring machines work almost wear-free.

The CNC measuring machines from THOME Präzision have covered guideways. Bellows protect our CNC coordinate measuring machines from dirt, damage and thermal influences. This means that the measuring machines can also be used close to production

Thanks to a well thought-out modular system, our measuring machines can be combined with almost any axis length. Depending on the measuring task, the axis lengths can be adapted to your needs.

Rigid probe head PH6 and high-precision measuring probe TP200 for use with star probes and, if required, with the SCR200 probe changing system.

Renishaw Probe head RTP20

Automatic turn and swivel head RTP20

RTP20 probe head with Renishaw MCR20 interchangeable magazine

Can be adjusted in 15 ° steps by moving the machine. Reproducibility 1.5 µm with a swivel radius of approx. 70 mm.

| # | Package 2 | Package 3 |

|---|---|---|

| Probe changer | Can be retrofitted | MCR20 |

| Probe head/ Probe | PH6/TP200 | RTP20 |

| Measurement software ThomControl |

Basic geometery | Basic geometery with CAD |

| Measuring range 900-1.200-800 |

€ 60,990 P1298-G-PH620-UK |

€ 63,490 P1298-C-RTP20-UK |

| Measuring range 900-1.500-800 |

€ 65,490 P1598-G-PH6200-UK |

€ 68,490 P1598-C-RTP20-UK |

| Measuring range 1.000-1.800-800 |

€ 72,990 P18108-G-PH6200-UK |

€ 75,490 P18108-C-RTP20-UK |

| Measuring range 1.100-1.800-900 |

€ 76,990 P18119-G-PH6200-UK |

€ 79,490 P18119-C-RTP20-UK |

| Measuring range 1.100-2.200-1.000 |

€ 83,990€ P221110-G-PH6200-UK |

€ 86,490 P221110C-G-RTP20-UK |

Pivots motorized in 2 axes in 7.5 ° steps (max. 720 positions). A position feedback is sent to the control. The reproducibility of the swivel position +/- 0.5 µm with a swivel radius of around 100 mm. Max. Length of the extension of the probe 300 mm. Max. Length of the stylus 60mm.

Suitable for the following applications:

Motorized rotary / swivel head PH10T and measuring probe TP200

Renishaw PH10T probe head

Renishaw SCR200 stylus change magazine

Renishaw PH10 series probe heads

Pivots motorized in 2 axes in 7.5 ° steps (max. 720 positions). The header position is reported to the control. The reproducibility of the swivel position +/- 0.5 µm with a swivel radius of around 100 mm. Max. Length of the extension of the probe 300 mm. Max. Length of the stylus 100 mm.

Benefits:

| # | Package 4 |

Package 5 |

|---|---|---|

| Probe changer | MCR20 |

SCR200 High precision |

| Probe head/ Probe | PH10T/TP20 |

PH10T/TP200 High precision |

| Measurement software ThomControl |

Basic geometery with CAD | Basic geometery with CAD |

| Measuring range 900-1.200-800 |

€ 70,490 P1298-C-PH1020-UK |

€ 71,490 P1298-C-PH10200-UK |

| Measuring range 900-1.500-800 |

€ 75,490 P1598-C-PH1020-UK |

€ 76,990 P1598-C-PH10200-UK |

| Measuring range 1.000-1.800-800 |

€ 82,490 P18108-C-PH1020-UK |

€ 83,490 P118108-C-PH10200-UK |

| Measuring range 1.100-1.800-900 |

€ 86,490 P18119-C-PH1020-UK |

€ 87.490 P18119-C-PH10200-UK |

| Measuring range 1.100-2.200-1.000 |

€ 93,490 P221110-C-PH1020-UK |

€ 94,490 P221110-C-PH10200-UK |

The Renishaw PH20 probe head in simultaneous panning

Renishaw PH20 swivel probe head

Renishaw PH20 5-axis probe head

Can control any angle in the room. The resolution of the angular positions is 0.15 sec. When measuring circles, the head-touch function can be used. This means that the probing speed is up to 5 times higher than with conventional machine movements.

| # | Paket 6 |

|---|---|

| Probe changer | TCR20 |

| Probe head/ Probe | PH20 Stepless 5-axis probe |

| Measurement software ThomControl |

Basic geometery with CAD |

| Measuring range 900-1.200-800 |

€ 74,490 P1298-C-PH20-UK |

| Measuring range 900-1.500-800 |

€ 79,490 P1598-C-PH20-UK |

| Messbereich 1.000-1.800-800 |

€ 86,490 P18108-C-PH20-UK |

| Measuring range 1.100-1.800-900 |

€ 90,490 P18119-C-PH20-UK |

| Measuring range 1.100-2.200-1.000 |

€ 97,490 P221110-C-PH20-UK |

Pivots motorized in 2 axes in 7.5 ° steps (max. 720 positions). A position feedback is sent to the control. The reproducibility of the swivel position +/- 0.5 µm with a swivel radius of around 100 mm. Max. Stylus length 400 mm.

| # | Package 7 Scanning |

|---|---|

| Probe changer | FCR25 |

| Probe head/ Probe | PH10M/ SP25 |

| Measurement software ThomControl |

Basic geometery with CAD |

| Measuring range 900-1.200-800 |

€ 81,490 P1298-C-PH10SP2-UK |

| Measuring range 900-1.500-800 |

€ 86,490 P1598-C-PH10SP2-UK |

| Measuring range 1.000-1.800-800 |

€ 93,490 P18108-C-PH10SP2-UK |

| Measuring range 1.100-1.800-900 |

€ 97,490 P18119-C-PH10SP2-UK |

| Measuring range 1.100-2.200-1.000 |

€ 104,490 P221110-C-PH10SP2-UK |